First, it helps in obtaining a high expansion volume. Needless to say, there is no way to replicate that process at home, so the texture and flavor of homemade Cheerios will never match the store-bought kind exactly (although I'm still tinkering to get ever closer…) The commercial version also uses ingredients not available to the home cook (in this case, modified wheat starch, which functions differently than flour).įor example, here's a quote from Clodualdo Maningat, Ph.D., corporate director of research and development and quality control, Midwest Grain Products Inc., Atchison, KS, describing why modified wheat starch is superior: “There are three textural and sensory benefits of using modified wheat starch in extruded, gun-puffed cereal. We're not just extruding dough here, like you do when you're making pasta, or even like commercial pasta makers do when they're making pasta, but in the cereal-making process, the extrusion is also the cooking process, which means that once the cereals are finished and packaged up, they are truly ready to eat. Now what's interesting to note here is that the whole point of this process is to end up with a product that is ready to eat.

#CHEERIO CEREAL UPDATE#

I haven't been able to verify this, though – if I find a source that will tell me conclusively or if General Mills will return my phone calls, I'll update this information.) However, sprayed on vitamins tend to taste horrible and can wash off in milk, so since original Cheerios doesn't have a sugar coating of any kind and has no bitter taste, I actually suspect that they use a type of heat-stable synthetic vitamins that can be added earlier. (Side note: This is the standard procedure for fortifying extruded cereals with vitamins. Thus, the vitamins are sprayed on at the end of the processing. Most vitamins, whether natural or synthetic, are sensitive little creatures and will denature if added before the extrusion process due to the excessive heat. Synthetic vitamins are then sprayed on the cereal. Or should I say, “lightly toasted,” as the lovely lady at Nature's Path described it when I called their offices… The paste is then pushed out of the chamber through a die, which is how the recognizable “O” shape is formed, then cut and dried.

This gelatinizes the proteins in the flour, which softens and binds the dough.

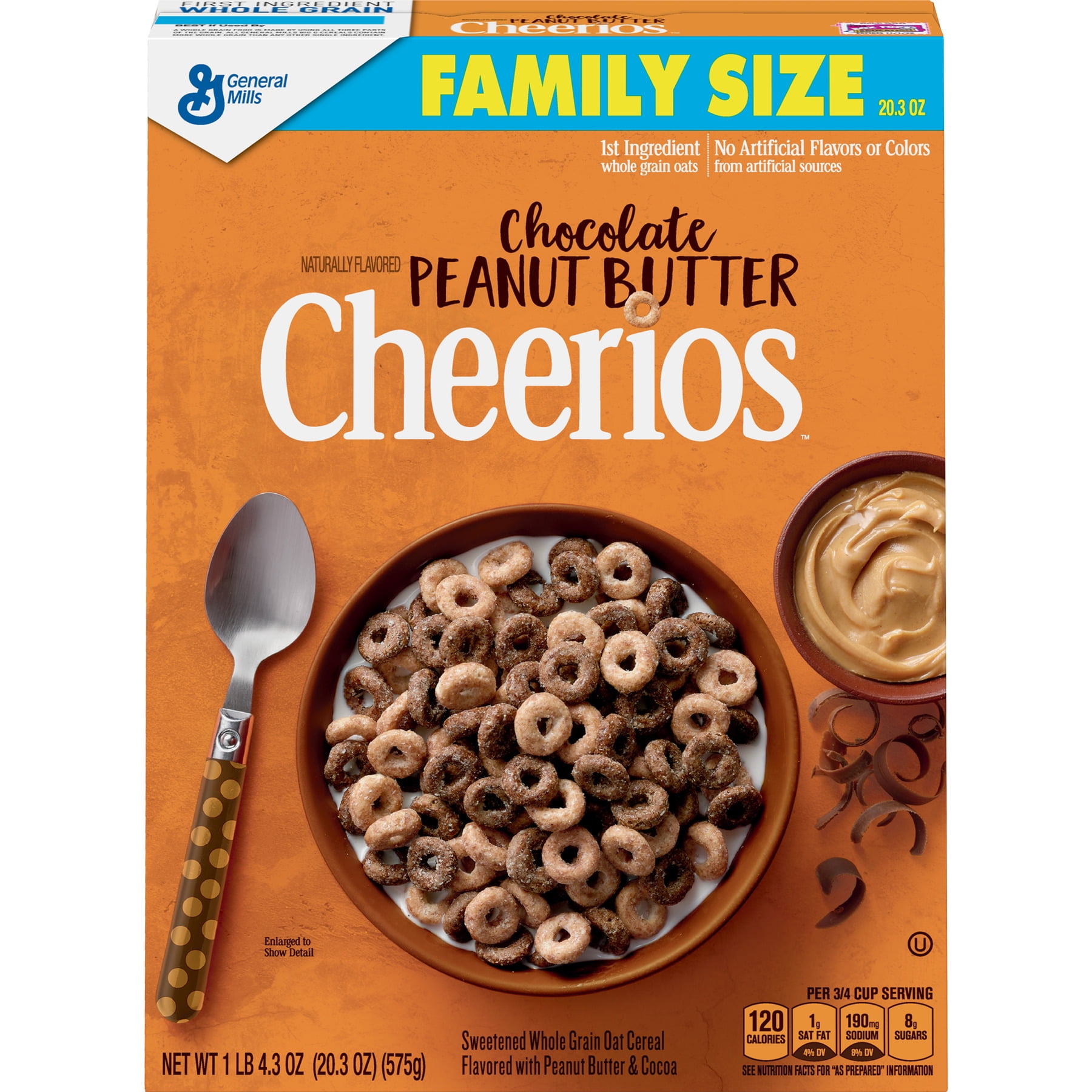

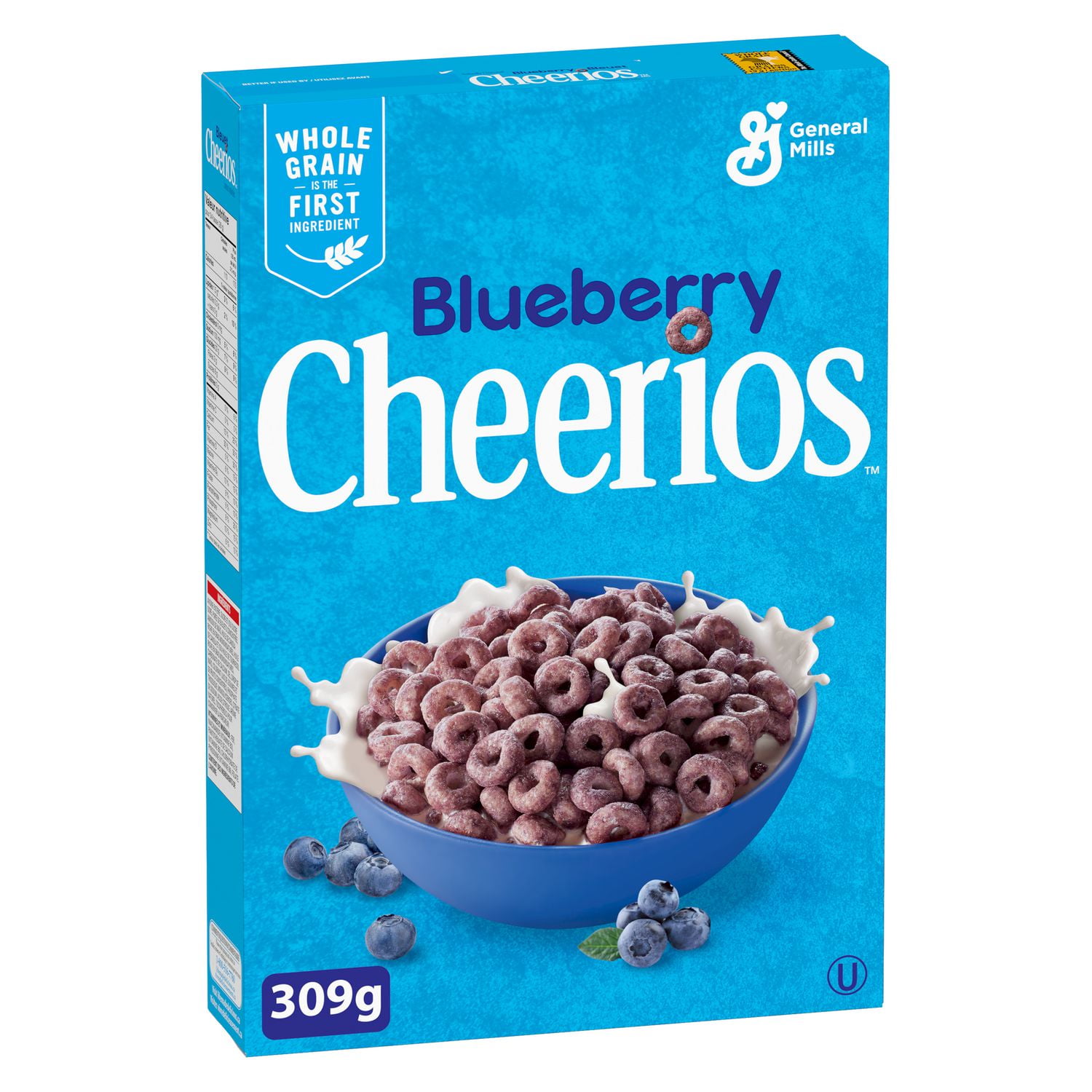

To make Cheerios, the flour is steamed inside a high-pressure chamber. It's all dry grains and starches (plus synthetic vitamins and preservatives)! What's especially interesting to me is that if you look at the list of ingredients on a box of Cheerios, there's not a single “wet” ingredient. How Cheerios Are Made (and why most store-bought cereals are detrimental to your health)

So, let's first take a look at how store-bought Cheerios are made so we can better understand the ingredients in homemade Cheerios. Others believe, however, that there is still at least one GMO ingredient lurking in the cereal.Īll this to say, you can make Cheerios at home!

#CHEERIO CEREAL DOWNLOAD#

Make using essential oils EASY with our at-a-glance cheatsheets.īe confident in using essential oils safely AND effectively! Simply click the button to download these two popular cheatsheets and see just how easy using essential oils SAFELY can be.

0 kommentar(er)

0 kommentar(er)